Factory

ISO 22000:2018 Certified Factory

Process

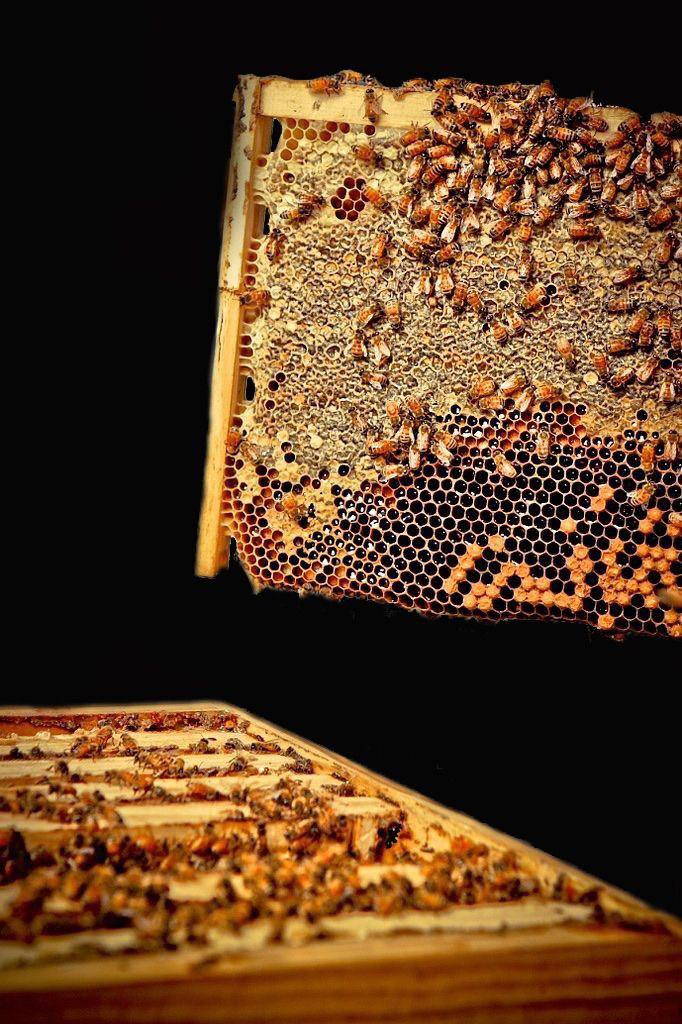

1. CENTRIFUGE AND FILTER RAW HONEY

After harvesting, honey is contained within honeycombs. Industrial centrifuges separate the honey from the honeycombs without affecting the hive's overall structure.

The honeycombs are then returned to the beehives, allowing the bees to resume their honey-storing work.

After centrifugation, the honey is in its raw form and passes through specialized screens to remove bee parts, wax, pollen, and other impurities before proceeding to the inspection phase.

2. INSPECTION AND FINE-FILTERING

The company eliminates samples that fail to meet quality standards.

Indicators of poor honey quality include unusual odor, abnormal color, sourness, or strange taste.

In-depth analysis checks for key criteria, such as C4 sugar content, total monosaccharide content, water content, aerobic microorganisms, HMF (Hydroxymethylfurfural), etc.

Honey that does not meet these standards is removed before entering the production process. Approved honey containers are labeled with harvest dates and detailed information for traceability. Samples are preserved and sent to the factory for further steps.

3. NANO FINE FILTERING

Honey that passes inspection and classification undergoes a final fine-filtering step.

The factory ensures the honey is completely free of impurities before entering the production process.

Using nano-filtering screens, the honey is placed in containers, and pressure is applied to remove any remaining impurities.

4. FUNGUS TREATMENT, ANTI-CRYSTALLIZATION, AND HONEY DEHYDRATION

This integrated process addresses three essential elements in honey production: fungus treatment, anti-crystallization, and honey dehydration using vacuum technology, maintaining a vacuum pressure of -760 mmHg.

The honey is processed in a vacuum environment and heated in a stirring tank at 20–30°C to eliminate bacteria and harmful fungi, ensuring quality and long-term preservation.

During this step, low-frequency ultrasound technology (27 kHz) is applied to perfect honey decrystallization.

Finally, the water content is reduced to approximately 18%, creating thick, flavorful honey. Water is removed at low temperatures to preserve honey quality.

The operation process is simple and seamlessly integrated into the production line.

5. VACUUM ENVIRONMENT STORAGE TANKS

Maintaining a vacuum environment after processing is crucial. Honey is stored in sealed containers under negative pressure to ensure a consistent water ratio and prevent contamination from insects or microorganisms before packaging.

6. SEALED PACKAGING LINE

Honey from the storage tanks is directly pumped into automatic bottling and packaging systems. This process enhances productivity while ensuring the honey's quality remains intact.