To produce delicious and high-quality honey, the production process is extremely important. So, how does the modern clean production process for processing honey work specifically?

The quality of honey is evaluated based on factors such as water content, sugar, HMF (hydroxymethylfurfural), etc. After harvesting, natural honey undergoes several steps to enhance its value.

Step 1 - Testing the Quality of Freshly Harvested Nectar

First, the company selects trays of ripe honeycomb. Then, they extract the raw honey, conduct preliminary filtration, and send samples for quality testing.

Step 2 - Removing Poor-Quality Honey

The company proceeds to eliminate samples of honey that do not meet quality standards. Some signs of poor-quality honey include unpleasant odor, unusual color, or sour taste.

Step 3 - Honey Processing

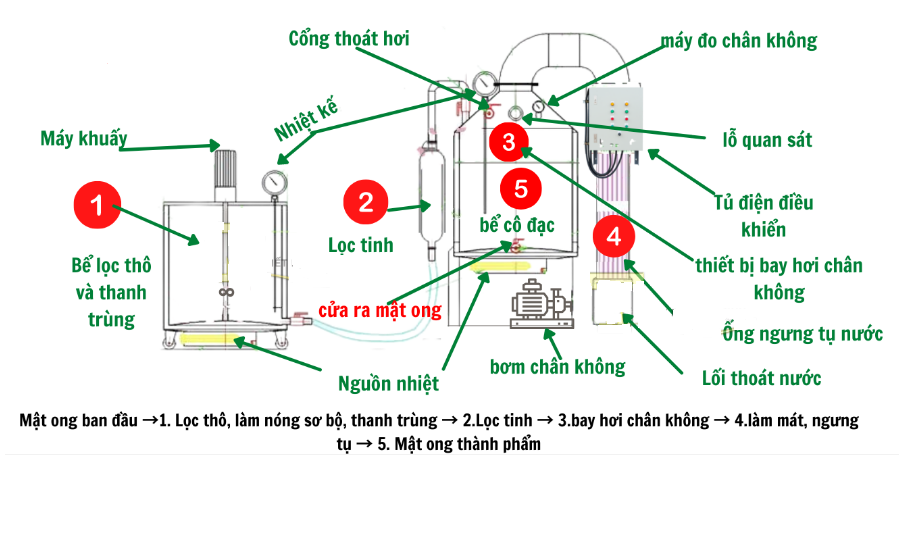

High-quality honey is taken to the processing plant, where the following steps are performed:

Fine filtering the honey using nano-mesh (ensuring food safety and removing pollen and impurities from the honey).

Eliminating yeast and fungi in the honey (ensuring the honey remains unchanged and safe for consumption).

Reducing the water content (ensuring honey meets the standard and extends its shelf life).

Decrystallizing the honey using ultrasonic wave technology (maintaining smooth consistency without re-crystallization).

Step 4 - Proper Storage

The high-quality honey is stored in a vacuum-sealed storage tank at an appropriate temperature. The honey storage tank must meet the following criteria:

Made of full stainless steel 304, equipped with sanitary valves (preventing bacterial growth and corrosion), and maintained at 21-26 degrees Celsius to preserve the quality of deeply processed honey.

Equipped with an automated filling machine using electronic scales and negative pressure.

Ensuring no foreign substances enter the honey until it reaches the final product stage.

Step 5 - Automated Bottling and Packaging:

The honey is automatically bottled and packaged on existing production lines. Afterward, the final products are delivered to distribution points to serve customers.

To implement this quality assurance process, the support of machines is indispensable, such as honey reducers, honey decrystallization machines, fungus treatment machines, etc.

These are all modern machines that apply advanced 4.0 scientific and technological techniques. Each type of machine has its specific function, contributing to the optimal quality of honey.

Thanks to these machines, the production process becomes professional, seamless, and meticulous. The quality of the honey meets European standards, optimizing the customer experience. So, what are the functions of these machines, and what are some common machine models available on the market?

Readmore